Engineering & Environment Product

Engineering Division ISO 9001, 14001 & OHSAS 45001 Certified Manufacturing Unit located at Kalyani, Nadia, West Bengal, on a sprawling 20 acre area with modern tools, gadgets and machineries to make the best Industrial Fans in India. Established 1959.

Product Range

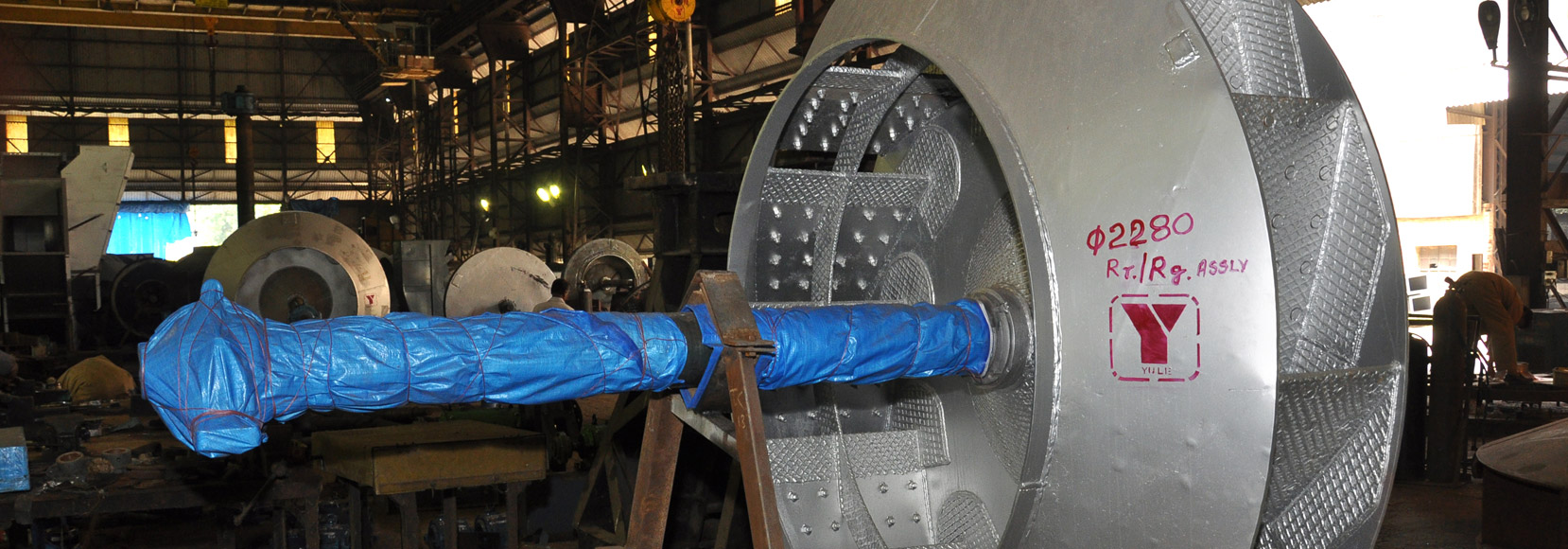

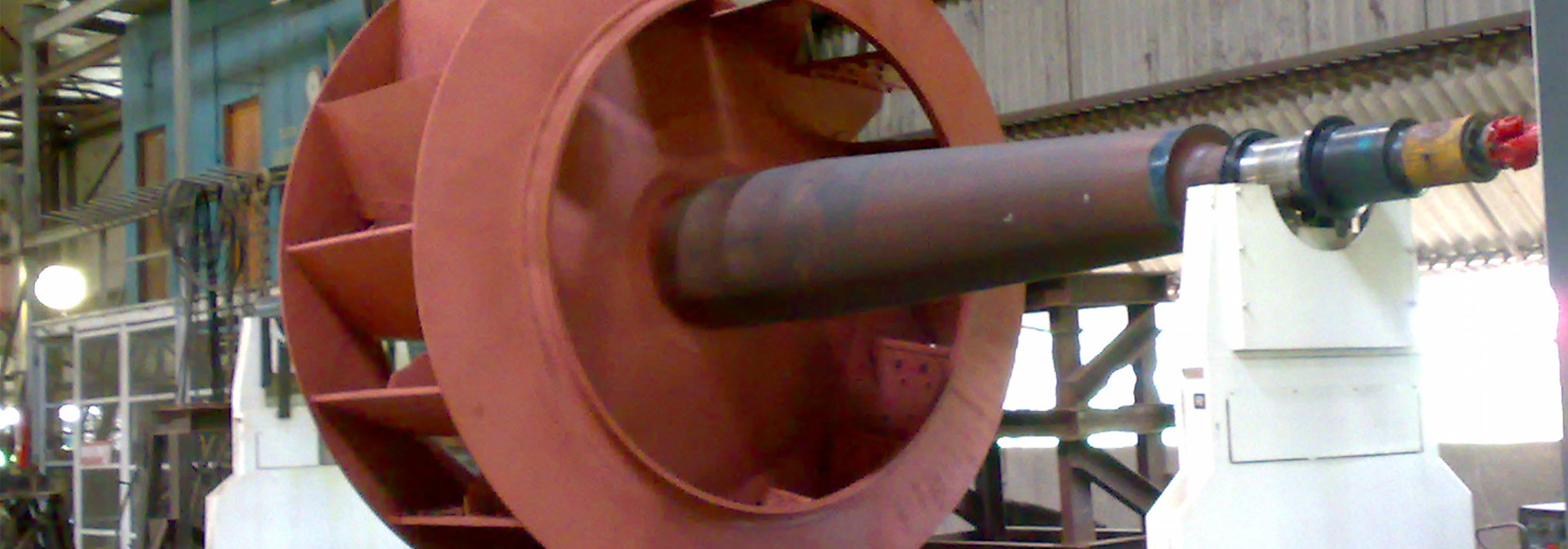

'YULE' Centrifugal Fan

- Flow Rate From 2000 M3/HR To 30,00,000 M3/HR.

- Pressure Upto 4900 MM WG.

- Temperature Upto 450 Deg.C (Continuous).

- Speed Upto 3000 RPM.

- Power Upto 6 Mw For Single Fan.

Model Capacity

- High Efficiency.

- Guaranteed Performance.

- Sound Mechanical Running, Low Noise.

- Quick Delivery.

- One Year On-Site Warranty (Excl. Wear Liners).

- Very Reliable Service Back-Up By Real Experts In The Field.

Speciality

'YULE' AIR Pollution Control

- Fume Extraction & Cleaning Systems.

- Gas Conditioning Towers.

- De-dusting Systems in Electric Arc Furnaces.

Electro Static Precipitator ( ESP )

'YULE' Water Pollution Control

- Effluent Treatment Plant for Industrial Applications.

- Chemical and Process Industries.

- Sewerage Treatment Plants for Municipal Applications.

- Water Treatment Plants.

Refurbishment of Waste Gas Fan Impeller

- Removal of Old Shaft from assembly.

- Refurbishment of old impeller.

- Blade Liners are to be replaced by new.

- All strength weld joints are to be DP tested and repaired if necessary.

- All Cone Sheet liners are to be replaced.

- New Shaft to be supplied and fitted.

- Balancing of Impeller & Shaft assay as per ISO 1940/1 G 2.5.

Scope of Work

For Further Details Please Contact :

Shri Amit Dutta

Dy. General Manager (Operations & BD), Engineering Division.

E Mail : gm.engg@andrewyule.com / gm_mkt.engg@andrewyule.com / amit.dutta@andrewyule.com

Phone No: (91-33) 2582 8279 / 5734

Fax No: (91-33) 2582 8581